Short project description

The aim of this project is to develop a lead-free complex nanostructure, for tailoring the gamma and neutron attenuation as well as rheological properties of cement-based mixtures suitable for 3D printing. To achieve this goal through a bottom-up approach, a nanostructure composed of bismuth oxide (Bi2O3), gadolinium oxide (Gd2O3) and silicon oxide (SiO2) will be developed. The overall objective of this work is to combine materials containing the high electron density (high Z) needed for gamma attenuation (Bi2O3) and the high interaction probability required to slow neutrons (Gd2O3), with a material which will improve their immobilization within the cementitious matrix (SiO2). By adjusting the nano-SiO2 content in the nanostructure, the rheological properties of a printable mixture can be optimized (controlled).

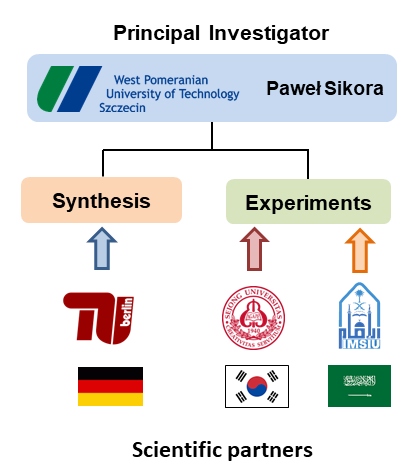

The proposed project will be implemented by an interdisciplinary and international research group composed of experts in the fields of rheology (Germany), radiation shielding (Saudi Arabia) and microcomputed tomography (South Korea).

Using the proposed methodology and based on experimental and numerical investigations, as well as micro- and macro-scale analyses, a fundamental understanding on the effects of nanosized admixtures on the properties of 3D printed composites will be obtained.

SONATA 16

SONATA 16